|

16.11.2016

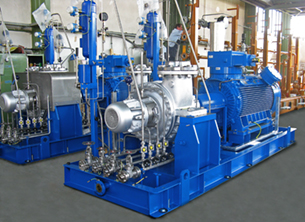

Moscow Refinery to be equipped with modern pumping units by HMS GroupHYDROMASHSERVICE (a part of HMS Group) has supplied a large batch of state-of-the-art pumping units for the modernization project in the Gazprom Neft Moscow Refinery. The pumping units manufactured by HMS Group companies will operate as part of the sulfuric-alkaline waste and process condensate treatment system being built. A total of 25 pumping units were supplied to the Moscow Refinery. Single-stage and multistage high-pressure process pumps will feed the system with raw material and pump petroleum products and working liquids. The pumps have high-efficiency hydraulics of the flow path and are made of highly resistant stainless steel. The supplied equipment is characterized by low vibration and smooth running. The construction of the treatment system for sulfuric-alkaline wastes and process condensate is being performed at the Moscow Refinery within the second phase of the large-scale modernization program that has been under implementation by Gazprom Neft since 2011. As a result, the refinery will significantly improve technical and ecological manufacturing features. The sulfuric-alkaline wastes and process condensate treatment system will become a part of the sewage treatment plant. The construction of Biosphere biological treatment plants is now taking place at the refinery. As a result of these projects, the Moscow Refinery will be able to achieve 99% purification efficiency by 2018. The fluid catalytic cracking unit will be retrofitted in the beginning of 2017. After the retrofit the capacity of the unit will rise by 20%, Gazprom Neft aims at turning the Moscow Refinery into the best refinery in Europe in terms of technical and environmental parameters. About 75 bln rubles were invested into the modernization program from 2011 to 2015. Due to these measures, the refinery twice reduced its environmental impact, including the reduction of fugitive emissions by 36%. The environmental impact will decrease by 50% more within the second phase of the modernization program. HYDROMASHSERVICE is one of the leading suppliers of pumping, modular and other equipment for the oil & gas industry, water Gazpromneft-Moscow Refinery is one of the industry’s leading producers of high-octane petrol and Euro-5 diesel

|

USEFUL LINKS

| |||||||||

- ProjectsSupporting materials

- | About us

- | Products

- | Services

- | Press-centre

- | Projects

- | Supporting materials

- | Contacts

- | Site map

125252, Moscow, 12 Aviakonstructor Mikoyan street

Phone: +7 (495) 664-81-71, fax: +7 (495) 664-81-72