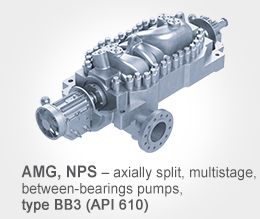

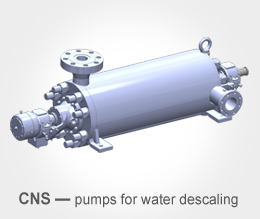

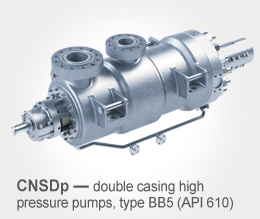

Pumping equipment upgradeHYDROMASHSERVICE conducts pumping equipment upgrade together with HMS Group manufacturers and specialized units. The main upgrade goal is not mere pump’s initial capabilities restoration but to improve the equipment structure with applying the most recent R&D achievements to pass them over for better customer satisfaction. We design and upgrade pumps and pumping assemblies, pumping stations for household and public utilities, oil & gas, chemical processing, thermal & nuclear power, supply spare parts and components to increase performance of older products and machines. The upgrades are performed according to the customer’s specific requirements or our specialists’ recommendations based on trends and evolving industry’s requirements. CNS pumps repair and upgrade for oil & gas The CNS pumps upgrade project consists of the nine basic stages:

|

USEFUL LINKS

|

- ProjectsSupporting materials

- | About us

- | Products

- | Services

- | Press-centre

- | Projects

- | Supporting materials

- | Contacts

- | Site map

125252, Moscow, 12 Aviakonstructor Mikoyan street

Phone: +7 (495) 664-81-71, fax: +7 (495) 664-81-72